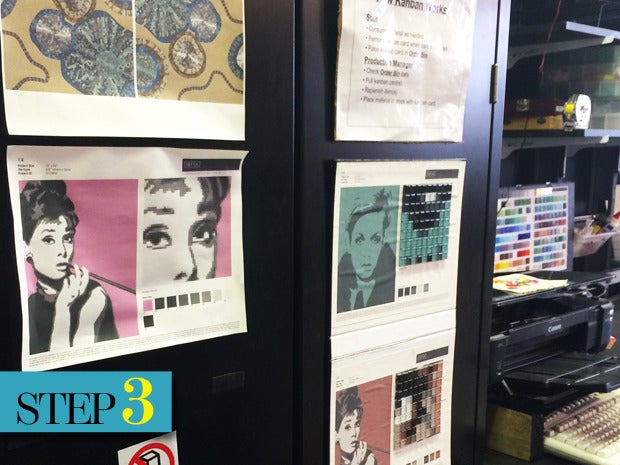

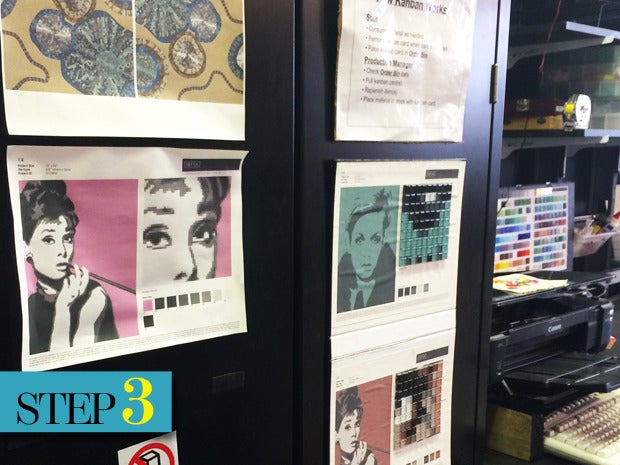

Artaic is a Boston-based startup that manufactures beautiful mosaic designs similar to those that have been produced throughout history. What’s different is that the company creates its art using technology and robots to produce thousands of patterns. Ted Acworth, Artaic’s founder and CEO, formed the company in 2007 after seeing a need for a faster, more efficient way to build mosaic designs, which historically has been a labor-intensive process.

“I looked at the tile industry [and] realized it’s a huge market,” he says. “People settle for boring tile because it’s too expensive to get beautiful, more artistic tile, [but] technology can enable more people to get more beautiful tile.”

Read CIO.com’s article on Artaic and watch our video on how Arty, the robot, speeds up the mosaic manufacturing process.